Step 1

Unboxing

Make sure you received all included parts of your product

▶ F/T Sensor with 3.0m cable

▶ Power supply with adapters

▶ USB cable adapter

▶ Ethernet cable adapter

Step 2

Electrical

Integration

▶ Choose from the two options below. ( BFT-MIPS-ENET-CG only support ethernet)

▶ Attach the sensor cable to the Ethernet port of the sensor marked with "ENET". Like on the picture.

▶ Connect the other end of the sensor cable to the Ethernet cable adapter to the port "Sensor" port.

▶ Plug an ethernet cable to the ethernet port marked with "" of the Ethernet Cable adapter and connect to an ethernet port of a computer or a network switch.

▶ To power the Sensor Plug the barrel connector of the provided power supply or use a PoE switch, in that case no external power is required.

▶ Connect a USB-C cable to the USB port of the Ethernet Cable adapter and to a laptop to configure the sensor

▶ Navigate with Chrome or Edge browser to the online configuration

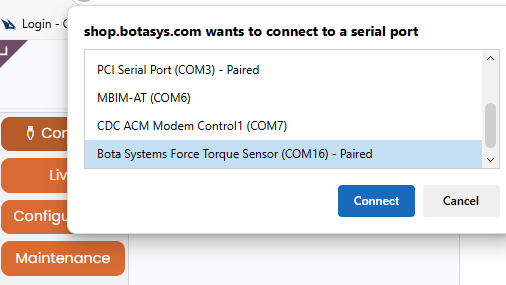

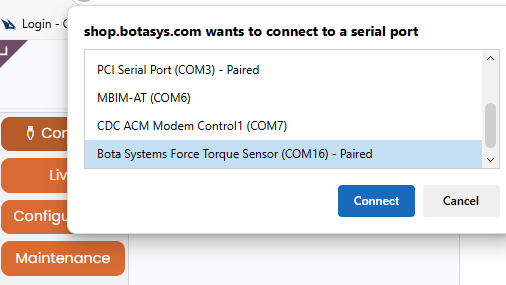

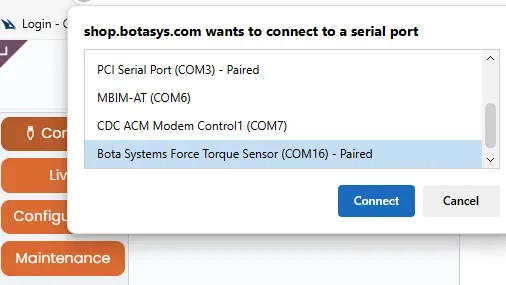

▶ Click "Connect" and select the sensor like on the picture

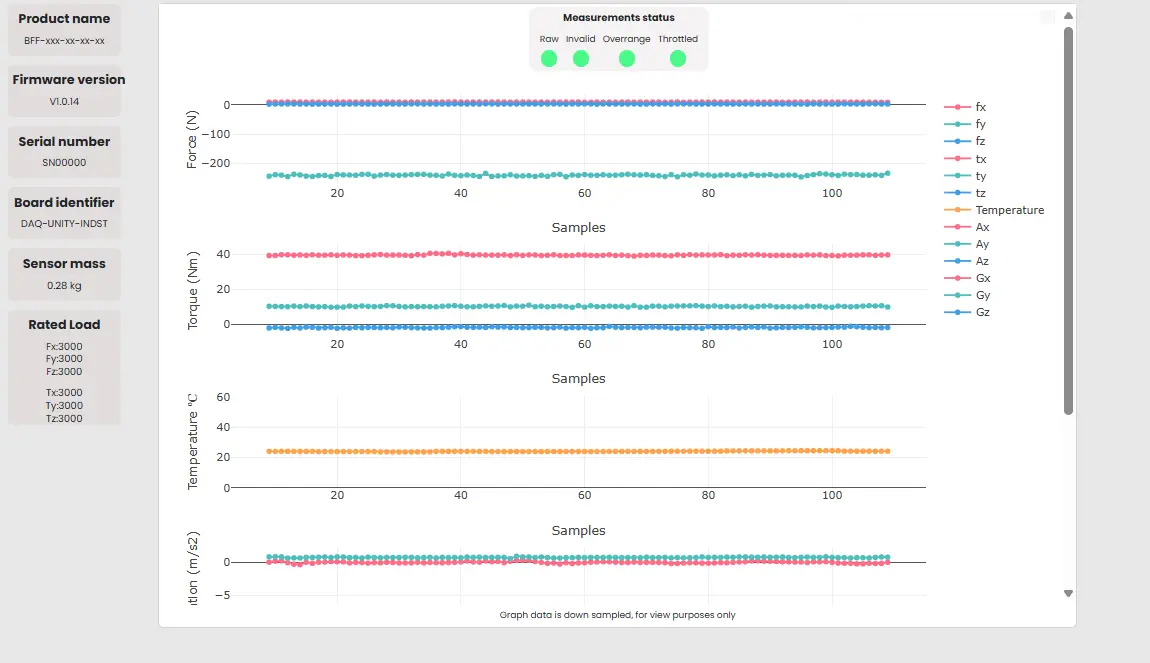

▶ You should see the sensor measurements shortly after and the sensor is having a solid green led.

▶ Click "Configuration" to modify the sensor parameters

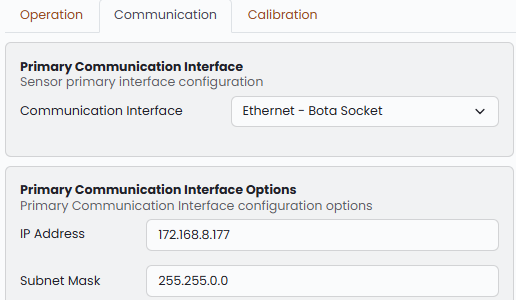

▶ Navigate to the "Communication" tab

▶ Under "Communication Interface" select:

Ethernet - Bota Socket or Ethernet - Modbus TCP

▶ On the card below all relevant options can be modified

▶ Click "Save" on the lower right corner to preserve the setup of the sensor after power off

▶ Attach the sensor cable to the Serial port of the sensor marked with "SERIAL". Like on the picture.

Damage can occur, If not connected to "SERIAL" port

▶ Connect the other end of the sensor cable to the Serial cable adapter on port "Sensor" (or use your own adapter see sensor's datasheet for pinout.)

▶ Connect a USB-C cable to the USB port of the Serial Cable adapter and to a laptop to configure the sensor

▶ Navigate with Chrome or Edge browser to the online configuration

▶ Click "Connect" and select the sensor like on the picture

▶ You should see the sensor measurements shortly after and the sensor is having a solid green led.

▶ Click "Configuration" to modify the sensor parameters

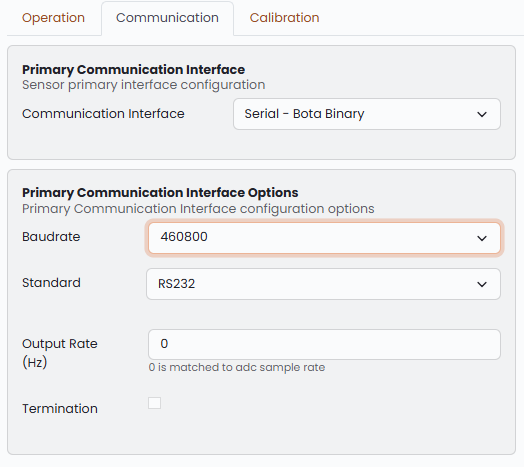

▶ Navigate to the "Communication" tab

▶ Under "Communication Interface" select:

Serial - Bota Binary or Serial - Modbus RTU or any other serial protocol Serial - ....

▶ On the card below the specific RS protocol can be selected. In case of RS485 or RS422 receiver termination can be enabled.

Reducing the Baudrate of the sensor will limit (throttle) the output data rate of the sensor.

To evaluate that the new baudrate is sufficient switch to the "Live" View and make sure the "Throttled" Indicator is green.

▶ The "output rate" is used to throttle the sensor measurements to a specific output rate. If 0 the output rate of the sensor would be the Update Rate (from tab "Operation").

▶ Click "Save" on the lower right corner to preserve the setup of the sensor after power off

▶ If RS232 was selected in the step above, connect an DB9 cable to the DB9 connector of the Serial Cable adapter

▶ If RS422 or Modbus was selected in the step above, connect an the RS422/485 wires on the screw terminals of the Serial Cable adapter (see product page for pinout)

▶ To power the Sensor after configuration, plug the barrel connector of the provided power supply to corresponding socket.

Step 3

Mechanical

Integration

Comply with the following requirements to ensure your sensor’s measurement quality

▶ Avoid mounting with non-rigid parts like 3D printed adapters.

▶ Clean the mounting surfaces from any dirt and debris.

▶ Do not under- or over-tighten the fasteners (see our user manual)

▶ Fix the sensor cable safe and steady on your system such that it does not apply any force to the sensor.

Bota Systems AG has developed a user-friendly driver to simplify the integration of sensors into your applications. The driver is a plug-and-play software package that makes configuring and reading data from Bota Systems' FT sensors easy and efficient for the most popular platforms, including C++, Python and ROS2. For more information see here.

This guide will integrates the sensor with a Python software, for a closed-loop control application that runs in 100hz and communicates with Ethernet.

▶ With the Sensor connected to a Computer with Internet access navigate to the Config Tool

ONLY, Chrome, and Edge Browsers are supported.

▶ Click on the button "Connect" on the top left corner and select the the sensor

If the sensor has been configured with any Ethernet communication the config tool can be access by typing the sensors IP on the Browser ensuring that the network setting have been properly configured.

▶ You should see the sensor measurements shortly after and the sensor is having a solid green led.

▶ Click the "Configuration" button on the top left.

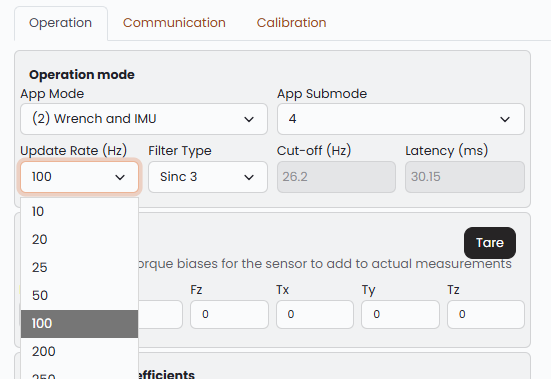

▶ Navigate to the "Operation" tab

▶ Under "Update rate" choose 100Hz to automatically select the "App submode"

▶Click "Save" on the lower right corner to preserve the setup of the sensor after power off

▶ The driver is configuring the sensor's operation parameters on startup using a configuration file. After modifying all parameters in "Operation" tab

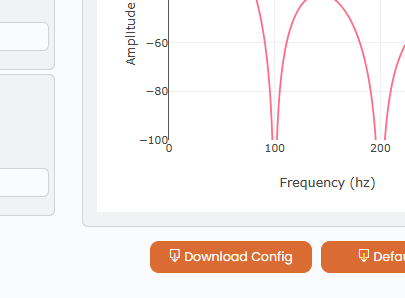

Click "Download Config" File

The file sets the "operation" parameters to the sensor and is using the "communication" parameters to connect to the sensor.

▶ Download and Install the prebuilt driver using the following command in command line with python and pip installed

pip install bota-driver

▶ Follow the instruction of the python examples to get measurements, there are available for Windows, Linux and Linux ARM architectures.